Skylink Imports Inc. is a trusted name in international sourcing and supply, renowned for its high-quality pharmaceutical vials. With a global footprint that includes headquarters in the USA, branches in Canada, and strong operational roots in India, the company specializes in sourcing, procurement, and logistics for a diverse range of products.

The pharmaceutical industry relies heavily on reliable suppliers of critical components like vials. Skylink Imports has established itself as a leader in this space, committed to delivering quality and reliability to its clients worldwide.

Key Takeaways

- Skylink Imports is a trusted global supplier of pharmaceutical vials.

- The company has a strong presence in the USA, Canada, and India.

- Skylink Imports is committed to quality, reliability, and customer satisfaction.

- The company specializes in sourcing, procurement, and logistics.

- Skylink Imports serves a diverse range of clients in the pharmaceutical industry.

Understanding Pharmaceutical Vials and Their Importance

Pharmaceutical vials are a crucial component in the medical and pharmaceutical industries, serving as a primary packaging solution for various drugs and medications. These vials are designed to store and transport pharmaceutical products safely, maintaining their potency and effectiveness.

What Are Pharmaceutical Vials?

Pharmaceutical vials are containers made typically from glass or plastic, used to hold injectable drugs, vaccines, and other pharmaceutical products. They come in various sizes and are designed to be sterile, ensuring the contents remain uncontaminated.

Critical Role in Medical and Pharmaceutical Industries

The critical role of pharmaceutical vials in the medical and pharmaceutical industries is undeniable. They are essential for storing and transporting medications, vaccines, and other pharmaceutical products, ensuring that these products remain safe and effective.

Impact of Vial Quality on Product Integrity

The quality of pharmaceutical vials directly impacts the integrity of the pharmaceutical products they contain. High-quality vials prevent contamination, ensure sterility, and maintain the product’s efficacy, making them vital for patient safety.

In conclusion, high-quality pharmaceutical vials are indispensable in the pharmaceutical industry, playing a critical role in ensuring the safety and efficacy of pharmaceutical products.

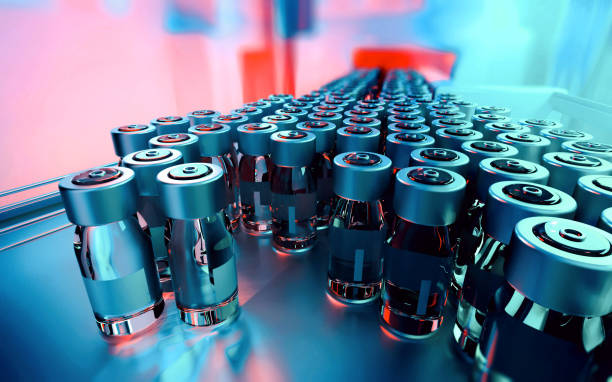

The Best Quality Pharmaceutical Vials by SKYLINK IMPORTS

With a commitment to quality, Skylink Imports offers a diverse range of pharmaceutical vials that meet stringent industry standards. The company’s product portfolio is designed to cater to various needs in the pharmaceutical and medical industries.

Overview of Skylink’s Pharmaceutical Vial Range

Skylink Imports provides a comprehensive selection of pharmaceutical vials, including clear glass vials, amber glass vials, and specialized vials for sensitive medications. Their product range is designed to meet the diverse needs of pharmaceutical manufacturers, research laboratories, and compounding pharmacies.

Quality Standards and Certifications

The company adheres to rigorous quality standards, ensuring that all vials are manufactured under strict guidelines. Skylink Imports holds various certifications, including FDA compliance and USP standards, guaranteeing the highest quality of its pharmaceutical vials.

Manufacturing Excellence

Skylink Imports’ manufacturing facilities are equipped with state-of-the-art technology, enabling the production of high-quality vials with precision and consistency. The company’s commitment to manufacturing excellence ensures that every vial meets the required standards, providing reliability and trust to its clients.

The company’s dedication to quality, combined with its comprehensive product range and adherence to industry standards, positions Skylink Imports as a leader in the pharmaceutical packaging sector.

Types of Pharmaceutical Vials Offered by Skylink Imports

Skylink Imports offers a diverse range of pharmaceutical vials designed to meet various medical and pharmaceutical needs. Their product line is tailored to cater to different requirements, ensuring that clients can find the right vials for their specific applications.

Clear Glass Vials

Clear glass vials are a popular choice for pharmaceutical applications where visibility of the contents is crucial. These vials are made from high-quality glass that is inert, ensuring that the contents remain unaffected by the container. Clear glass vials are ideal for medications that require inspection or have specific storage needs.

Amber Glass Vials

Amber glass vials are used for light-sensitive medications, as they protect the contents from UV light. This type of vial is essential for drugs that degrade when exposed to light, ensuring their potency and effectiveness. Amber glass vials offer a reliable solution for storing sensitive pharmaceutical products.

Specialized Vials for Sensitive Medications

Skylink Imports also offers specialized vials designed for sensitive medications that require unique storage conditions. These vials are engineered to provide additional protection against environmental factors, ensuring the stability and efficacy of the medication.

Custom Solutions

Understanding that different clients have unique needs, Skylink Imports provides custom solutions for pharmaceutical vials. Whether it’s a specific size, material, or closure system, the company works closely with clients to develop tailored packaging solutions that meet their exact requirements.

By offering a wide range of durable vials and custom solutions, Skylink Imports supports the pharmaceutical industry’s need for high-quality, reliable packaging. Their diverse product line ensures that clients can find the perfect pharmaceutical containers for their products.

Material Quality and Durability Features

At Skylink Imports, the focus on material quality and durability sets their pharmaceutical vials apart in the industry. The company utilizes borosilicate glass, a material renowned for its exceptional chemical resistance and thermal stability.

Borosilicate Glass Advantages

Borosilicate glass is the preferred material for pharmaceutical vials due to its low thermal expansion coefficient, which makes it highly resistant to thermal shock. This characteristic is crucial for maintaining the integrity of pharmaceutical products during storage and transportation.

Chemical Resistance Properties

The chemical resistance of borosilicate glass ensures that it does not react with the pharmaceutical products it contains. This property is vital for preserving the efficacy and safety of the drugs.

Temperature Tolerance

Skylink Imports’ vials can withstand a wide range of temperatures, making them suitable for various pharmaceutical applications. The table below summarises the temperature tolerance of their borosilicate glass vials.

| Temperature Range | Borosilicate Glass Performance |

|---|---|

| -80°C to 200°C | Excellent thermal stability |

| Autoclaving Conditions | Withstands high-pressure steam sterilization |

| Cryogenic Storage | Maintains integrity at extremely low temperatures |

The combination of borosilicate glass advantages, chemical resistance properties, and temperature tolerance makes Skylink Imports’ pharmaceutical vials a reliable choice for the pharmaceutical industry.

Design Specifications and Customization Options

Skylink Imports understands the importance of tailored packaging solutions; their pharmaceutical vials are available with various design specifications and customization options. This flexibility allows pharmaceutical companies to choose vials that perfectly match their product requirements.

Size Variations and Capacity Options

Skylink Imports offers a diverse range of vial sizes to accommodate different volumes of pharmaceutical products. The capacity options vary from small vials for precise dosing to larger vials for bulk storage. The size variations are designed to meet the specific needs of various pharmaceutical applications.

| Vial Size | Capacity (ml) | Diameter (mm) | Height (mm) |

|---|---|---|---|

| Small | 2-5 | 12-15 | 20-25 |

| Medium | 10-20 | 18-22 | 30-40 |

| Large | 50-100 | 25-30 | 50-60 |

Closure Systems and Sealing Technologies

The closure systems for Skylink Imports’ vials are designed to ensure secure sealing and prevent contamination. Various sealing technologies are employed, including crimp seals and screw caps, to provide a tight and secure closure. The choice of closure system depends on the specific requirements of the pharmaceutical product.

Custom Branding and Labelling Possibilities

Skylink Imports also offers custom branding and labelling options for its pharmaceutical vials. This allows pharmaceutical companies to personalise their packaging with their logos, product information, and other relevant details. Custom branding enhances product recognition and compliance with regulatory requirements.

By offering a range of design specifications and customization options, Skylink Imports enables pharmaceutical companies to create packaging solutions that are both functional and tailored to their brand identity.

Compliance with International Pharmaceutical Standards

Skylink Imports prioritizes compliance with international pharmaceutical standards to ensure the highest quality of its products. This commitment is reflected in their rigorous adherence to various regulatory requirements and industry standards.

FDA Compliance

Skylink Imports ensures that their pharmaceutical vials meet the stringent requirements set by the FDA, guaranteeing safety and efficacy for use in medical applications. FDA compliance is a critical aspect of their quality assurance process.

USP Standards

The company adheres to the United States Pharmacopoeia (USP) standards, which dictate the quality, purity, and safety of pharmaceutical packaging. USP standards are crucial for maintaining the integrity of pharmaceutical products.

International Pharmacopoeia Requirements

Skylink Imports also complies with International Pharmacopoeia requirements, ensuring its products meet global standards for pharmaceutical packaging. This compliance facilitates the global distribution of their products.

Quality Certifications

The company’s commitment to quality is further underscored by various quality certifications that demonstrate its adherence to international standards. These certifications are a testament to Skylink Imports’ dedication to excellence.

Skylink Imports: Global Operations and Expertise

Skylink Imports’ global footprint is a testament to its commitment to delivering high-quality pharmaceutical packaging solutions. With a strategic presence in multiple countries, the company has established a robust network that caters to the diverse needs of the pharmaceutical industry.

USA Headquarters and Operations

The United States serves as the headquarters for Skylink Imports, where the company oversees its global operations. The USA office is pivotal in managing the company’s international business, ensuring compliance with global standards, and driving innovation in pharmaceutical packaging.

Canadian Branch and Services

In Canada, Skylink Imports operates a dedicated branch that provides specialized services to the North American market. The Canadian office collaborates closely with local clients, providing customised solutions that cater to the unique needs of the Canadian pharmaceutical industry.

Indian Manufacturing and Sourcing Capabilities

Skylink Imports has leveraged India’s manufacturing capabilities to produce high-quality pharmaceutical vials. The company’s Indian operations are equipped with state-of-the-art facilities, enabling efficient sourcing and production that meet international quality standards.

International Distribution Network

Skylink Imports boasts an extensive international distribution network that ensures timely delivery of its products to clients worldwide. The company’s logistical capabilities are designed to support the global pharmaceutical supply chain, providing reliability and efficiency.

Key aspects of Skylink Imports’ global operations include:

- Strategic locations in the USA, Canada, and India

- Compliance with international pharmaceutical standards

- State-of-the-art manufacturing facilities

- Efficient global distribution network

Quality Control and Testing Processes

Skylink Imports is committed to delivering premium pharmaceutical vials, backed by comprehensive quality control measures and testing protocols. Ensuring the highest quality of pharmaceutical vials is crucial for maintaining product integrity and safety.

Inspection Methodologies

The inspection process at Skylink Imports involves rigorous visual inspections to detect any defects or irregularities in the vials. Advanced technologies are utilized to ensure precision and accuracy in the inspection process.

Automated inspection systems are employed to check for parameters such as dimensional accuracy, surface quality, and packaging integrity. This ensures that every vial meets the required standards before it is shipped to customers.

Testing Protocols and Standards

Skylink Imports adheres to stringent testing protocols that comply with international pharmaceutical standards. The testing protocols include chemical resistance testing, thermal shock testing, and hydrolytic resistance testing to ensure the vials’ durability and compatibility with various pharmaceutical formulations.

- Chemical resistance testing to evaluate the vials’ resistance to chemical reactions.

- Thermal shock testing to assess the vials’ ability to withstand extreme temperature changes.

- Hydrolytic resistance testing to determine the vials’ resistance to water and other solvents.

Quality Assurance Guarantees

Skylink Imports provides quality assurance guarantees for its pharmaceutical vials, ensuring that they meet the highest standards of quality and reliability. The company’s commitment to quality is reflected in its certifications and compliance with regulatory requirements.

Sustainability and Environmental Considerations

As a leader in pharmaceutical packaging, Skylink Imports prioritizes eco-friendly manufacturing processes. Our commitment to sustainability is evident in our comprehensive approach to reducing environmental impact.

Eco-Friendly Manufacturing Practices

We have implemented various eco-friendly manufacturing practices to minimize our carbon footprint. This includes optimizing production processes to reduce energy consumption and waste generation.

Recyclable Materials

At Skylink Imports, we emphasize the use of recyclable materials in our products. Our pharmaceutical vials are made from high-quality borosilicate glass, which is not only durable but also fully recyclable.

Reduced Carbon Footprint Initiatives

We are committed to reducing our carbon footprint through various initiatives, including energy-efficient lighting and renewable energy sources in our facilities.

Sustainable Packaging Solutions

Our packaging solutions are designed with sustainability in mind. We offer customizable packaging options that minimize waste and reduce the environmental impact of our products.

| Sustainability Initiative | Description | Impact |

|---|---|---|

| Eco-Friendly Manufacturing | Optimized production processes | Reduced energy consumption |

| Recyclable Materials | Use of borosilicate glass | Fully recyclable products |

| Carbon Footprint Reduction | Energy-efficient practices | Lower greenhouse gas emissions |

Applications and Industries Served

The pharmaceutical vials provided by Skylink Imports are utilized in a multitude of applications, showcasing their adaptability and quality. Their vials are designed to meet the stringent requirements of various industries, ensuring the safe storage and transportation of pharmaceutical products.

Pharmaceutical Manufacturing

Skylink Imports’ vials are widely used in pharmaceutical manufacturing for packaging a variety of drugs and vaccines. Their high-quality vials ensure the integrity of the products, complying with international standards.

Research Laboratories

In research laboratories, Skylink Imports’ vials are used for storing and handling samples and reagents. The chemical resistance and durability of their vials make them ideal for such applications.

Compounding Pharmacies

Compounding pharmacies also benefit from Skylink Imports’ vials, using them for custom medication preparations. The vials’ precision and reliability are crucial in these settings.

Biotechnology Applications

In biotechnology applications, the vials are used for storing biological samples and materials. Skylink Imports’ vials are designed to maintain the integrity of these sensitive materials.

The diverse applications of Skylink Imports’ pharmaceutical vials highlight their versatility and the trust they have earned across different industries. Some of the key benefits include:

- High-quality materials and construction

- Compliance with international standards

- Customization options for specific needs

Conclusion: Partnering with Skylink Imports for Premium Pharmaceutical Packaging Solutions

Skylink Imports has established itself as a leading provider of high-quality pharmaceutical vials, catering to the diverse needs of the medical and pharmaceutical industries. By partnering with Skylink Imports, businesses can benefit from their extensive range of premium pharmaceutical packaging solutions.

The Best Quality Pharmaceutical Vials by SKYLINK IMPORTS are designed to meet the stringent requirements of the pharmaceutical industry, ensuring the integrity and safety of medications. With a strong commitment to quality, reliability, and customer satisfaction, Skylink Imports is the ideal partner for companies seeking top-grade pharmaceutical packaging.

By choosing Skylink Imports, businesses can leverage their global operations, expertise, and commitment to sustainability, ensuring that their pharmaceutical packaging needs are met with the highest standards. Partnering with Skylink Imports enables companies to focus on their core activities while relying on a trusted partner for their packaging requirements.

Email us: info@skylinkimports.com

Contact us: Canada: +1 (403) 266-9394

India: +91-9041-543543 (WhatsApp Available)

USA: +1 (917) 672-6581